Reforming Brass: From One Cartridge to Another

The 8mm Mauser (7.92x57mm) round, in it’s current incarnation, has been around since 1903. It is a improvement of the original 7.92x57mm cartridge that was developed in 1888 by Peter Paul Mauser. Arguably, 8mm Mauser has been one of the world’s most popular cartridges, having seen significant military and civilian use over the past 100+ year. It also influenced the design of many of today’s cartridges, such as .30-06.

Finding good 8mm Mauser ammunition (in Canada at least) is becoming harder. The glut of military surplus rifles and ammunition for this cartridge is long over, and there are more modern cartridges which have gained a significant following.

The solution to the scarcity of 8mm Mauser is to hand load your own ammunition. Generally speaking all of the components necessary for reloading 8mm Mauser are common enough that a competent hand loader need not worry about having a supply of 8mm Mauser on hand.

Lately this seems to have changed (in Canada at least). The availability of 8mm Mauser brass seems to be drying up – it’s hard to find on the range (leftover by those who do shoot this cartridge), and buying commercial brass can be expensive.

One option available to the hand loader is to reform brass from another cartridge to 8mm Mauser. Note that while I’m talking about 8mm Mauser, these principles can apply to pretty much any cartridge; for example reforming .223 brass to 300BLK.

Reforming Brass

Forming brass isn’t as bad as it sounds. Brass is a soft metal, and can be easily shaped without using to much specialized equipment or force. Not all brass cartridges can be reformed to 8mm Mauser. As a general rule of thumb, anything that is a derivative of 8mm Mauser and is as long or longer that the 8mm Mauser case can be reformed. A good example would be .30-06 Springfield or .270 Winchester. Both are very common hunting cartridges in North America.

This picture shows the brass and reloading dies that I use to reform:

From left to right:

- Original .270 Winchester brass.

- Redding Form & Trim die for 8mm Mauser.

- .270 Winchester after the reforming die.

- Reformed .270 Winchester, after a rough cut to remove excess material.

- 8mm Mauser full length resizing die.

- Reformed .270 Winchester brass, after full length resizing.

- New piece of 8mm Mauser brass: trimmed to 2.230", chamfered, deburred, and annealled.

Collecting tools and components

The first step is to collect the necessary materials and tools. In my case I gathered up:

- A bunch of .270 Winchester brass, donated to me by a fellow at the range who had the foresight to collect his brass and the generosity to give it to me.

- Lee Precision Resizing Lube.

- Redding Form and Trim Die for 8mm Mauser (SKU 749-003-765WB). RCBS also makes trim die. Some people will just run their brass through a full length resizing die. I this case, I opted to use a reforming die.

- Hack saw.

- 8mm Mauser full length resizing die.

- Tools to trim, chamfer, and deburr brass.

- A good friend who knows how to anneal.

The process

Once I had everything, it was necessary to prep the brass. I tumbled it to clean it up, and then lubed each case. So far, nothing different for reloading any metallic cartridge.

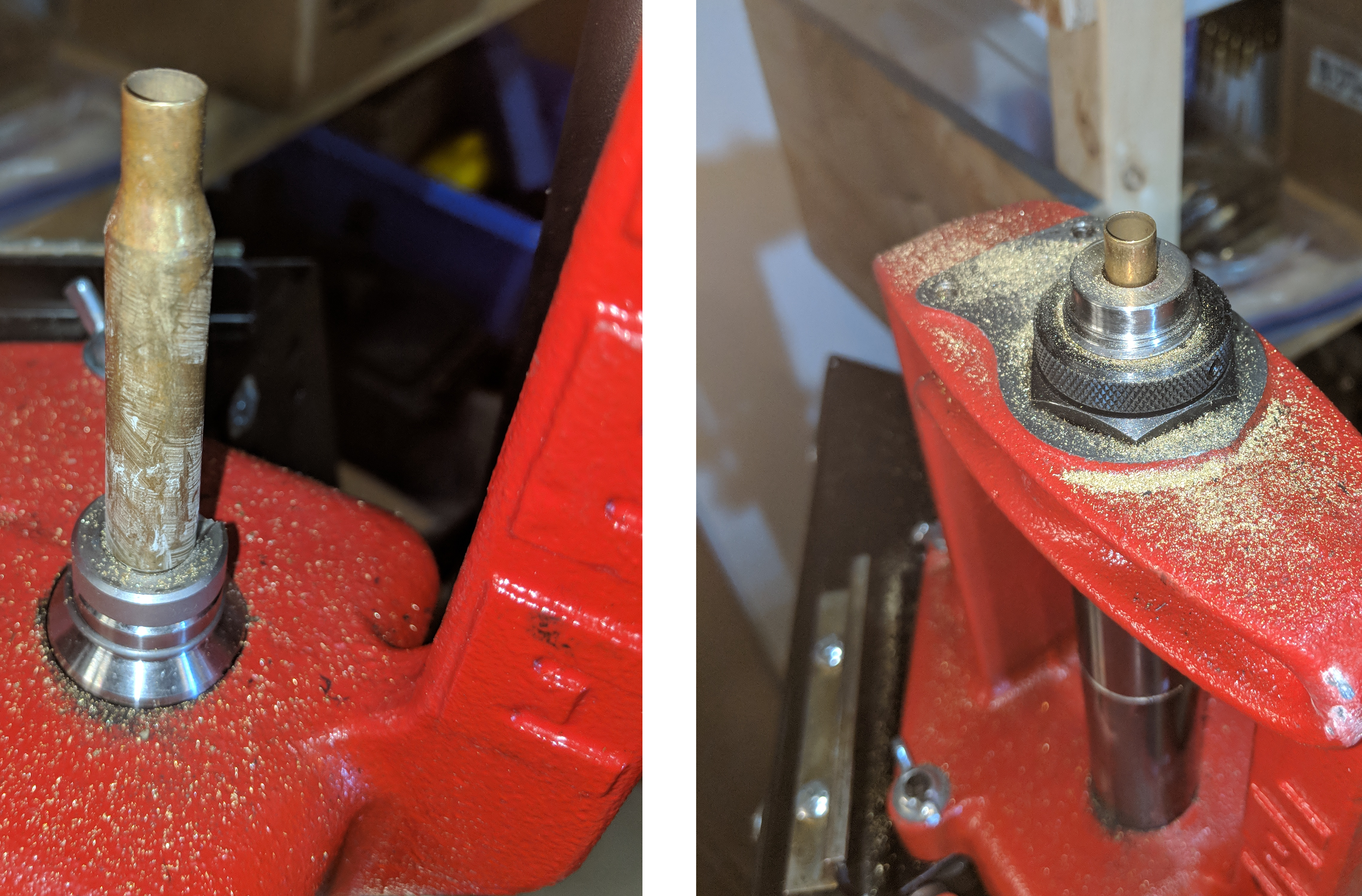

I took each piece of brass, and ran it through the reforming die. I didn’t lower the ram of the reloading press immediately, I left it up:

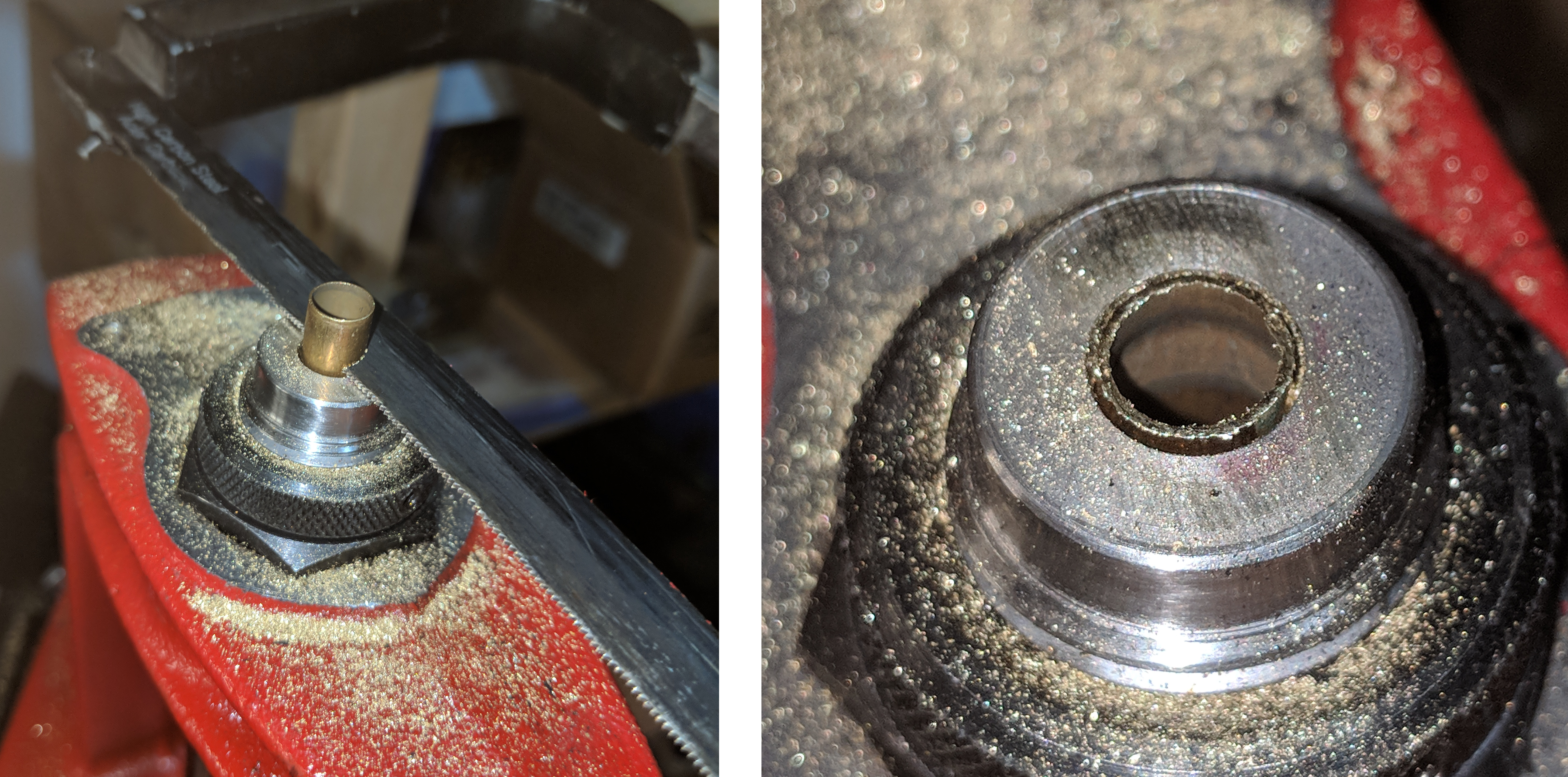

With the ram all the way up, I used my trusty hacksaw to trim away the excess material from the case:

After performing this rough cut on each piece of brass, I’d lower the ram, take the brass out, and quicking inspect the mouth of the case to make sure there weren’t any significant burrs around the mouth of the cartridge. Any burrs should be removed before proceeding on to the next step.

After reforming and making the rough cut, I pressed the brass through my full length resizing die. I didn’t find it necessary to lube the case a second time. Note that if there are excessive burrs on the case of the mouth, the full length sizer may mangle the piece of brass, rendering it useless.

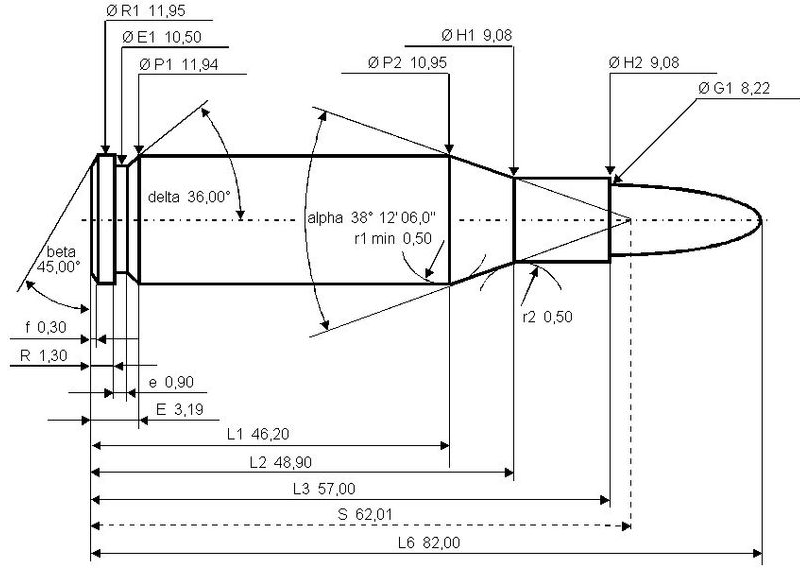

Finally I would trim the brass to the SAAMI spec for 8mm Mauser, and then deburr it. It is recommended to trim the case to 2.230", and the maximum length of the case must not exceed 2.240". This diagram shows the SAAMI spec for 7.92x57mm (dimensions are in millimetres):

Afterwards, I had the brass annealled. This is necessary because the steps involved with reforming and resizing the brass will result in it being “work hardened”. This means that the brass has become brittle and hard as a result of the forces being used to reshape it. The case necks will quickly crack due to the pressure generated when the cartridge is fired.

At this point, I can have prepped brass, ready for the process of being primed, charged with gunpowder, and being topped off with a projectile.